Are your products guaranteed?

CS Cavity Sliders are backed by our 10 Year Guarantee. Click to view our Warranty Conditions and Warranty Claim Form.

Welcome to our Frequently Asked Questions section, where you'll find answers to common queries about CS Cavity Sliders and our services.

CS Cavity Sliders are backed by our 10 Year Guarantee. Click to view our Warranty Conditions and Warranty Claim Form.

Yes - if we are manufacturing a NewYorker, then it will always come pre-finished. Timber and Alutec doors are usually supplied ready to paint.

Our systems are custom made to your required size. We hold stock and make units to suit a standard door size e.g. 2040 x 820mm or custom make to suit a large opening on-site. All CS Cavity Sliders products go through our rigorous quality assurance high-standard manufacturing processes.

Yes, we have multiple showrooms:

Sydney Showroom:

1056-1062 Canley Vale Road, Wetherill Park. NSW 2164

Victoria:

4/11-12 Phillip Ct, Port Melbourne VIC 3207

The Quality. Our units are unique in the way we construct them using aluminium joinery and extruded aluminium tracks. Depending on the brand you compare, there are different levels of quality and standards within the market. All of our units are the highest quality available - they need to be because you do not want a cheap product installed inside your wall! To stand by our products, we offer a written 10 year warranty on all of our cavity sliders.

Our cavity frames are manufactured from high quality extruded aluminium and high grade renewable timber resources.

We recommend 35-38mm thick doors for most of our systems. Multiple OvertakingDoors units are best used with 38mm thick doors. If your door is 40mm plus in thickness just ask for our Ultimate cavity slider system which can accommodate doors up to 88mm thick!

Generally speaking, we can supply a cavity slider system to suit any door size. For massive doors that are over 4m high and 5m wide, please consult us - we have solutions available!

A pair of single (M6) carriages will take 90kg. If your door happens to be heavier we have heavy-duty carriages available to suit doors up to 240kg (M8) or if your door is heavier still, step up to our M10 (500kg) carriage series.

RakingHead (self closing) units suit doors up to max. 50kg.

SofStop (soft closing) units suit doors up to max. 100kg.

SlimSlider units suit 70mm framework.

Standard units will suit 90mm framework.

Ultimate units require 140mm framework.

Overtakingx2 units require 140mm framework.

Overtakingx3 units require 190mm framework.

We are the experts - so if you have an unusual stud width and a large project, just reach out!

Our cavity and sliding doors specified without the CS SofStop comply as the operating force is less than 20 N. The clear opening of the width of the doorway must be 850mm. In the case of bi-parting double doors, the clear opening applies to the active leaf. Refer to AS1428.1.2021.10.3 for guidelines to observe proper clearance for circulation space.

Our CL400 Magnetic DDA is designed to comply with Australian Standard® AS1428.1.2021

For proper installation:

Door controls that need to be grasped or turned must be 900-1100mm high.

We custom manufacture our door systems at our factory in Sydney and distribute Australia wide. We also have stock holding capacity. Click here for a list of resellers in your area.

If required, we can organise delivery nationwide. Our commitment to high quality means we want your product to arrive at your delivery address in the same condition as when it left our factory. For this reason, we are very particular about who we allow to transport our product and this means using Furniture Transporters to send our goods to you.

Your order may take a bit longer to arrive than with standard freight carriers, but should arrive in excellent condition.

If you require urgent or overnight delivery and are happy to take the risk, you will need to organise your own freight.

Contact us to request a credit application form.

A Track Stop is needed when no physical stops are present, i.e., your door does not come to rest at a closing jamb or wall stud.

Example: A pair of bi-parting doors or a surface sliding track.

A CS SofStop mechanism is designed to slow down the door. It must be paired with a physical stop such as a "Track Stop" or closing jamb to ensure the mechanism does not break.

To use the CS SofStop in your project, your door must meet minimum door width requirements. Please review the table on the CS SofStop product page to confirm that your door is compatible.

1. Stand with your back against the door’s closing jamb

2. Look directly into the door’s cavity

3. Determine which side you’d like your snib (Privacy Function) or key on.

Example:

The homeowner would like to add a lock to this bathroom. Upon

positioning themselves and looking into the cavity, the homeowner’s

RIGHT hand is inside the bathroom. Therefore, the door’s handing would be: Right Hand (RH) Snib/Left Hand (LH) Emergency

CS Cavity Sliders can be configured with a full ply panel instead of nogs on one or both sides of the Cavity Frame, ideal for additional fixing like grab or towel rails in bathrooms and even some cabinetry. Cavity Sliders frames meet AS 1720.1, 2010 requirements, supporting up to 50kg/m² as tested. Follow the manufacturer’s instructions for installation compliance.

We are a manufacturer only. Our products can be installed by any competent builder. All units are supplied with complete installation instructions.

Pre-finished items should be cleaned regularly (at least once every 6 months in interior applications and more often in industrial or exterior environments) with a dilute solution of mild, neutral liquid detergent, e.g., dish washing detergent, warm water (40˚C), and a soft, lint free cloth or brush.

Do not use abrasive cleaning tools such as steel wool, hard brushes, abrasive scourers, etc., as these may damage the coating surface and change the colour or gloss levels of the finish. Rinse suds off thoroughly with fresh water and dry with a clean cloth.

It is vital that any other chemicals such as petrol, strong alkalines or acids are NOT used on any prefinished surface. Pre-finished items that are maintained regularly should retain their good looks. They will not crack, chip or peel as with conventional finishes.

For more information, please refer to the data sheet for Pre-finished Aluminium products here.

For more information, download the 'How to' instruction sheet. This explains how to remove a cavity sliding door from a CS Cavity Slider in depth.

How to remove the door from a CS Cavity Slider

Many pre-finished powder-coated products available from CS FOR DOORS are also available in a primed state ready for top coating on site by a paint professional.

This information sheet contains detailed top coat preparation and application instructions as recommended by the manufacturer of the primer.

By following these instructions you will ensure a high quality finish that matches the product supplied!

Click here to download our maintenance manual containing care instructions and warranty information.

If care is taken during the installation process, then in most cases there is no need for further maintenance.

The most common time for dust to accumulate is during building works. For this reason, we recommend taping up the track after installing the cavity slider, but before applying wall linings. This helps to prevent dust, debris or paint build-up during construction.

After installation, regular maintenance is not required. However, if you notice a change in the way the door runs or sounds, a quick inspection of the carriages and aluminium track running surface is recommended. The track can be cleaned with compressed air or wiped down with a soft rag.

CS cavity slider tracks feature a convex wheel channel, which causes less friction and dust build up. This also makes the system quieter and smoother running. If care is taken during the installation process, then in most cases there is no need to do anything further. The most common time for dust to accumulate is during building works. For this reason, we recommend taping up the track after installing the cavity slider, but before applying wall linings. This helps to prevent dust, debris or paint build-up during construction. After installation, regular maintenance is not required. However, if you notice a change in the way the door runs or sounds, a quick inspection of the carriages and aluminium track running surface is recommended. The track can be cleaned with compressed air or wiped down with a soft rag.

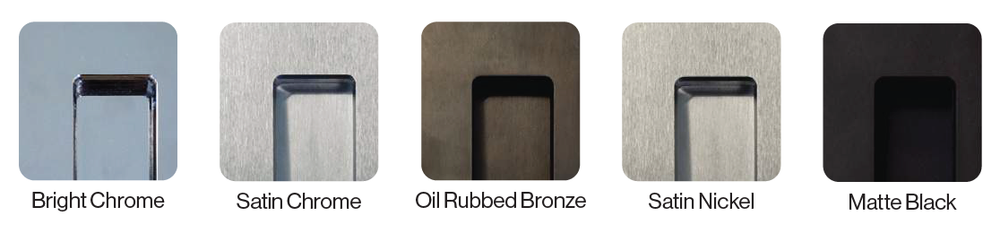

CL400 Magnetic and CL205 Ranges are available in the following finishes.

Other hardware options are available in Satin Chrome.

For detailed instructions on installing your CS Cavity Sliders products, please refer to the following links:

Need help with your installation? Contact one of our experts here

For detailed templates and fitting instructions, check out our Installation Page. For videos, check out our CaviLock Installation Series.

Need help with your installation? Contact one of our experts here

Can't find what you're after? Try our Knowledge Hub

FAQ - Frequently Asked Questions

Thank you!

Your submission has been sent.